It is suitable for various fields in the solar energy plant or PV system. Product performance standards: IEC61215, TUV 2Pfg-2007 and UL4703.

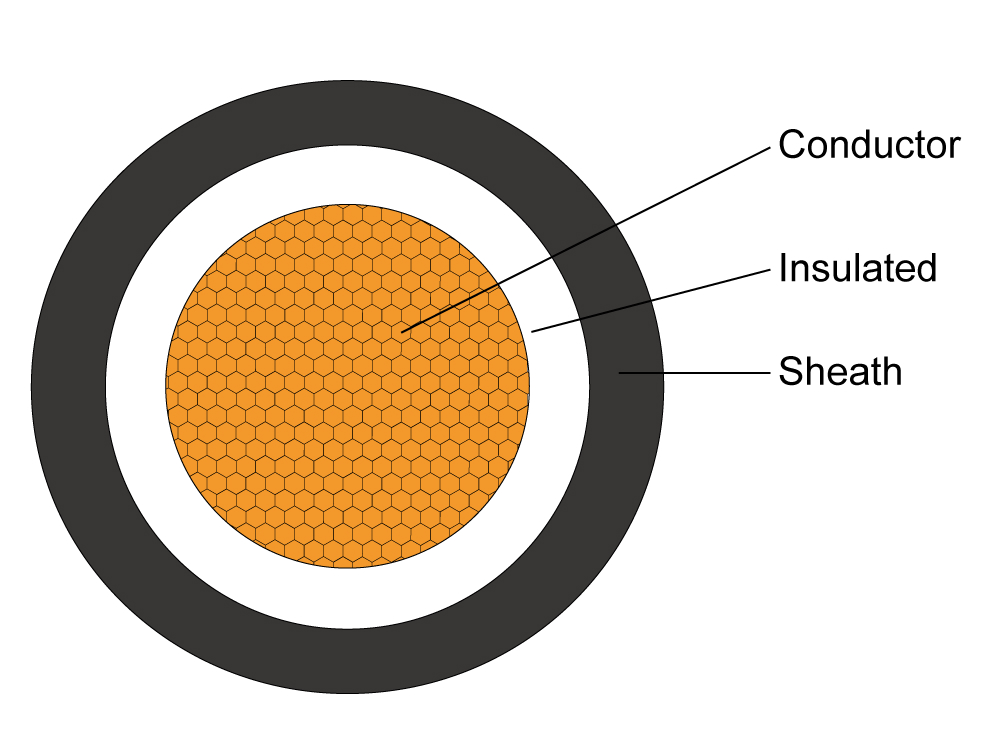

1.Conductor resistance at 20℃ meets the standard requirements. Sheath surface resistance is ρ≥109 Ω.cm.

2.The temperatureof waterpressure test is 20±5℃, immersion length 10M,one hour, Ac power frequency voltage 8000V, maintain 5min not breakdown.

3.Vertical burning test: Fixed point and the carbonation beginning point distance ≥ 50mm; burning down retardant to fixed-point distance ≤ 540mm. Combustion gas corrosion test: pH value≥4.3, conductivity ≤10μs/mm.

4.Inner insulation mechanical properties, the tensile test before aging: tensile strength ≥ 5N/mm2,elongation at break ≥ 200%; after aging (135 ± 2 °C), tensile strength change ≤ ± 30%, elongation at break change ≤ ± 30%. Airbomb aging tensile test: air pressure is 5.5 bar (127 ° C); tensile strength change ≤ + 30%, elongation at break change ≤ + 30%. Hot drawing test: oven temperature is 250 ± 3℃, mechanical pressure20N/cm2, Load elongation ≤ 100%, elongation after unloading≤ 25%.

5.Sheath mechanical properties of stretchingbeforeaging: tensile strength ≥ 10.0N/mm2; elongation at break change ≥300%; after aging (85±2℃): elongation at break ≥ 250%; tensile strength change ≤ ± -15%;elongation changesat break less than -25%.

PV1-F